Dry Ice Blasting - How it works

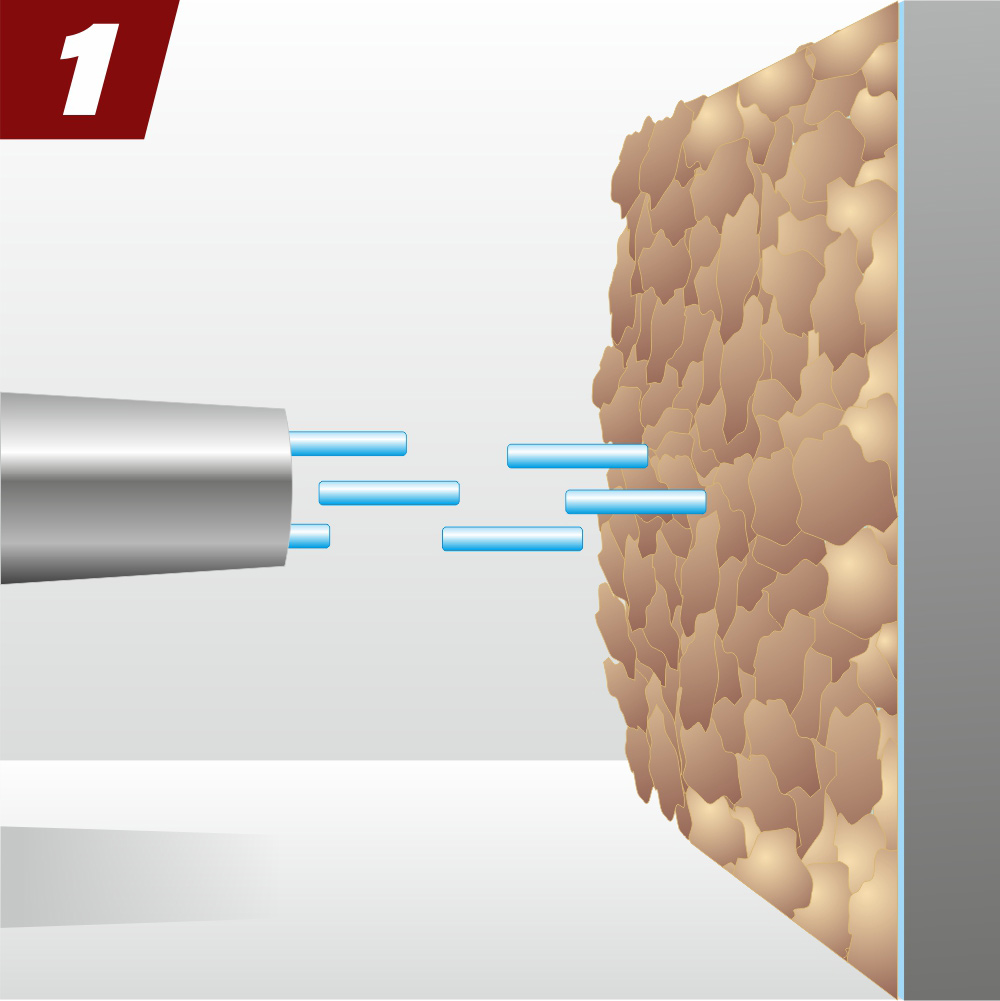

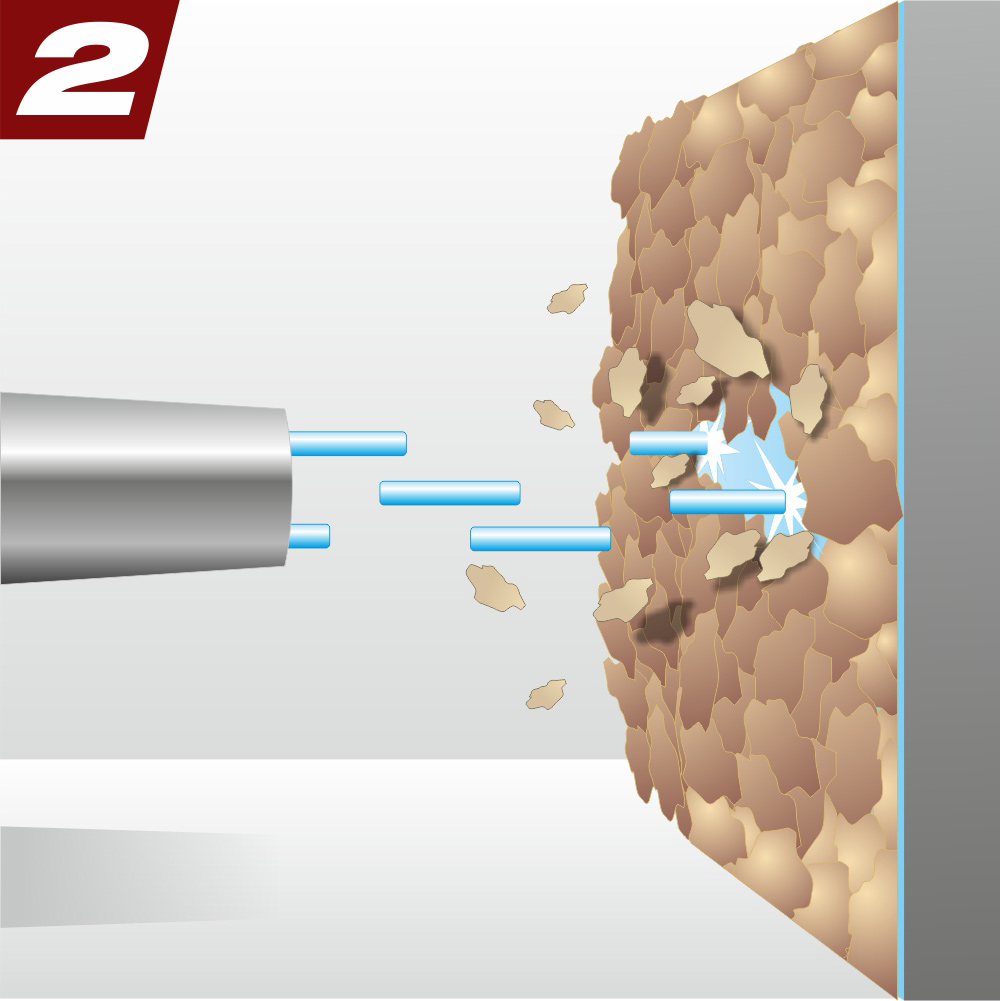

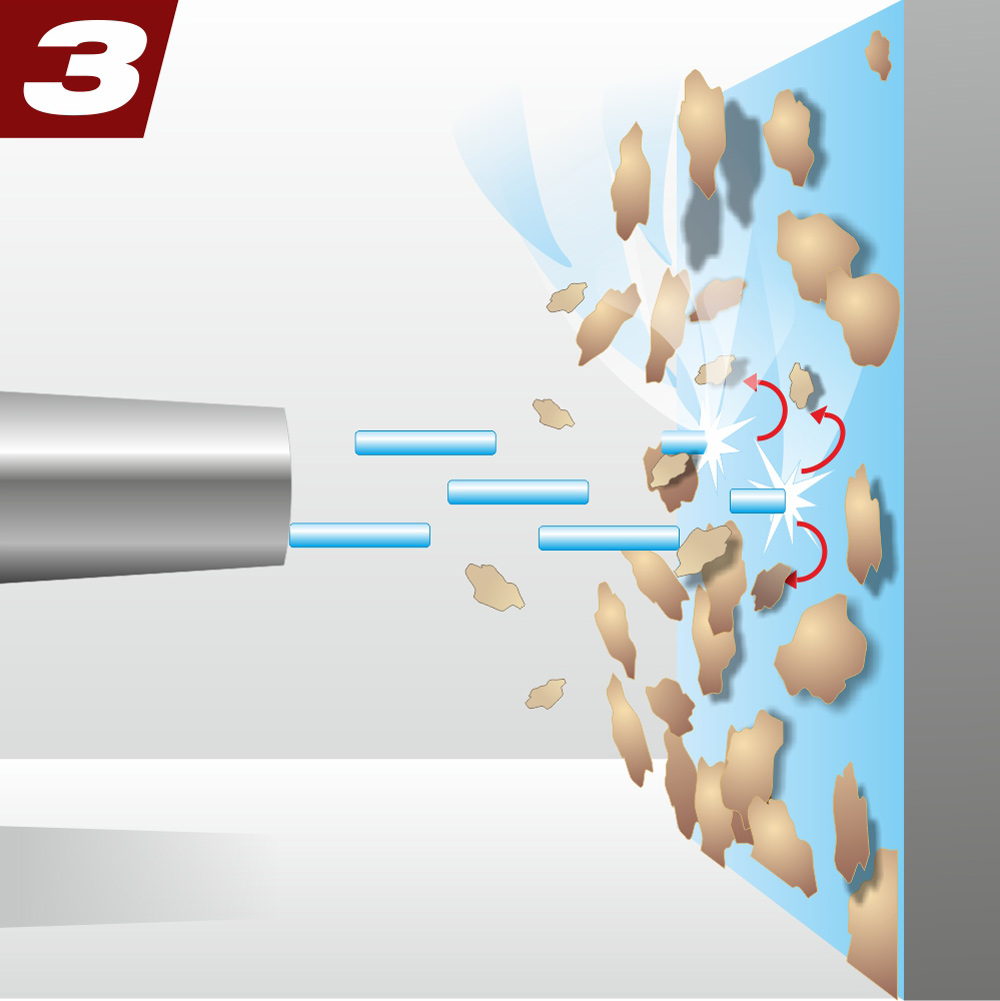

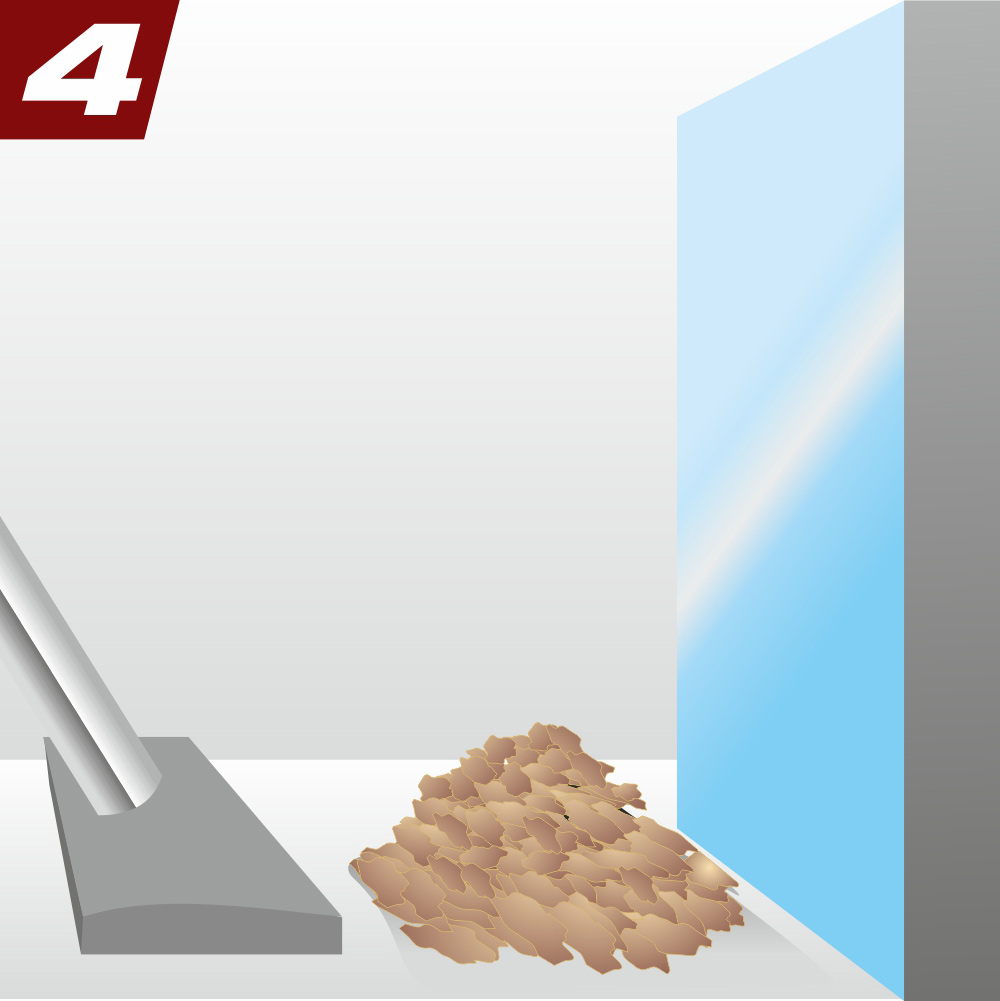

| Dry-ice blasting involves a gentle cleaning process that is not comparable to sandblasting or similar techniques. The big difference is that dry-ice blasting is a non-abrasive process, meaning no material is removed, changed, or damaged. The respective surfaces are only cleaned, and that in an impressive manner. There is hardly a type of undercoating, old oil remnants, or other type of dirt that cannot be removed with this technique. In addition to the traditional approach of removing all undercoating, other materials like rubber, plastic, and cables can easily be cleaned. The entire interior of the vehicle or engines with all subassemblies are therefore excellent candidates for this unbeatable cleaning method because the dry-ice blasting leaves behind not even a trace of moisture. In contrast to this is sandblasting, which is an abrasive process that removes material and results in friction heating of the surface to be processed. This means, for example, that sandblasting sheet metal can result in deformations which can often make the rest of the project more difficult and sometimes even impossible. The result can be that this warped sheet metal has to be replaced, even if it was fine before the blasting. In order to avoid misunderstandings, it should be said that sandblasting is indeed a very important procedure in the vehicle restoration process. However, it is completely inappropriate for the removal of old undercoating. You can find more information about the proper uses for sandblasting under this menu item. The following graphics are showing the dry-icing process in detail: |

The technical background of dry-ice blasting Dry ice, as used as a blasting abrasive in vehicle restoration, is derived from liquid CO2 (carbon dioxide). This gas is not flammable, has no odor, and is about 1.5 times heavier than air. At a temperature of just -79°C (-110°F), the gas solidifies, and it is produced in the form of small 3mm-thick pellets for use of a blasting abrasive. For the actual blasting process, these dry ice pellets are shot across the surface being worked on at a speed of more than 150 meters per second. Upon impact, the extremely cold (-79°C / -110°F) pellets immediately supercool the undercoating to be removed, making it brittle, which then allows additional dry-ice particles to penetrate the resulting cracks. The dry ice changes directly to its gaseous state immediately upon impact, sublimates, and increases its volume by a factor of about 700. The old undercoating and the dirt are literally blasted off. The only thing remaining is the dirt that was removed because the blasting abrasive, here the dry ice, escapes into the atmosphere as carbon dioxide. This is an extremely advantageous factor, because the blasting abrasive does not find its way into corners of the car (as is the case with sandblasting), and does not have to be removed in a subsequent step. Due to the gasification, both the surfaces to be worked on and the byproducts are completely dry because there is no moisture involved. |

| You can find more information here: | Dry Ice Blasting - Description & Pictures |

| Dry Ice Blasting - Benefits & Applications | |

| Dry Ice Blasting - Our Service |